hardness test rockwell pdf|hardness test lab report pdf : custom This document contains test procedures for quantitative and comparative analysis of Rockwell hardness on metal evidence. To evaluate a surface hardness gradient (e.g., due to carburizing Tudo pronto para começar? Use o Apresentações Google pa.

{plog:ftitle_list}

Intro: Nadson O Ferinha Mais uma pros apaixonados! Éh-ré. Verso: Nadson O Ferinha Imagino sua boca aqui na minha boca A gente acordando juntinho sem roupa Cafezin' .

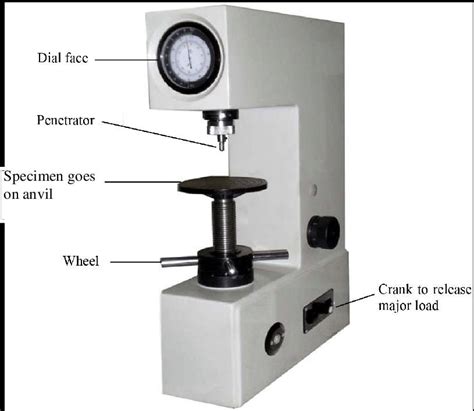

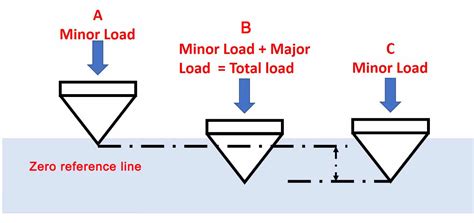

The hardness of a material by this Rockwell hardness test method is measured by the depth of Penetration of the indenter. The depth of Penetration is inversely

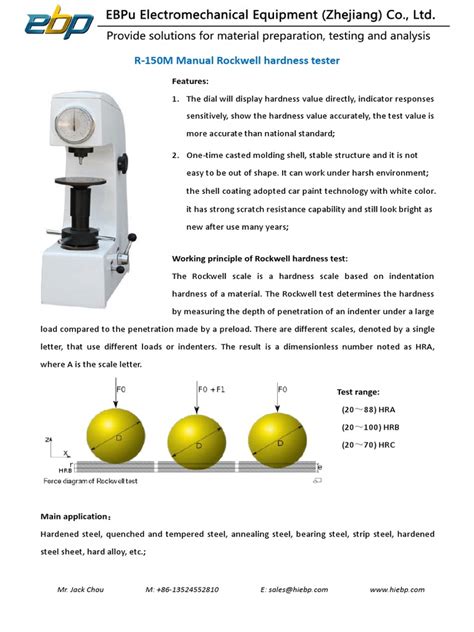

The Rockwell test is based on measurement of the depth of penetration with the hardness number read directly from the dial gauge or digital display that is part of every tester. In .Scope* 1.1 These test methods cover the determination of the Rockwell hardness and the Rockwell superficial hardness of metallic materials, including test methods for the .Rockwell superficial hardness tests. The significant differences between the two tests are that the test forces are smaller for the Rockwell superficial test than for the Rockwell test. The .This document contains test procedures for quantitative and comparative analysis of Rockwell hardness on metal evidence. To evaluate a surface hardness gradient (e.g., due to carburizing

Rockwell hardness test using Rockwell hardness scale is one of the extensively used and accurate hardness test methods prevalent in industries for thin steel, lead, brass, zinc, aluminum, cemented carbides, iron, titanium, .5.1.1 There are two general classifications of the Rockwell test: the Rockwell hardness test and the Rockwell superficial hardness test. The significant difference between the two test classifications is in the test forces that are used. For the Rockwell hardness test, the preliminary test force is 10 kgf (98

ISO 6508-3:2015, Metallic materials — Rockwell hardness test — Part 3: Calibration of reference blocks 3 Principle An indenter of specified size, shape, and material is forced into the surface of a test specimen under two force levels using the specific conditions defined in Clause 7. The specified preliminary force is applied The Rockwell hardness test continues to be applied as a tool for assessing the properites of a product while the tolerances on the acceptable material hardness have become tighter and tighter. Adhering to good practice procedures when performing Rockwell hardness measurements and calibrations is a beneficial step to reducing measurement errors.

3.1.7.3 portable Rockwell hardness testing machine a Rockwell hardness testing machine that is designed to be transported, carried, set up, and operated by the users, and that measures Rockwell hardness by the Rockwell indentation hardness test principle. 3.1.7.4 movable Rockwell hardness testing machine a Rockwell hardness testing machine .

this: Rockwell hardness testers are usually less costly than optical hardness testers, the test itself is quick and easy, surface finish of the material is not critical, and the Rockwell scale is a commonly accepted value when purchasing products. Applications for Rockwell Methods The Rockwell hardness test is widely used in various industrialDownload Free PDF. Hardness Testing Lab (Brinell and Rockwell) Mashhood Shah. 2020, Hardness Testing Lab (Brinell and Rockwell) . This study investigates the effects of hardening and physical factors on Al 2024 Alloy's hardness by the application of Rockwell hardness test. Its main goal is understanding the concept of hardness and examining .test force. 3.1.7 Rockwell hardness machine—a machine capable of performing a Rockwell hardness test and/or a Rockwell super-ficial hardness test and displaying the resulting Rockwell hardness number. 3.1.7.1 Rockwell hardness testing machine—a Rockwell hardness machine used for general testing purposes.

Rockwell regular hardness =100 0 002 − h, HRBW HREW HRFW HRGW HRHW HRKW Rockwell regular hardness =130 0 002 − h, HRN HRTW Rockwell superficial hardness =100 0 001 − h, 5 Rockwell hardness 5.1 The following is an example of the designation of Rockwell hardness. EXAMPLE 70 HR30TW, where:In this revision the requirement of method for Rockwell superficial hardness test, calibration of standardized blocks and verification of Rockwell hardness testing machines have been included. In the preparation of this standard, assistance has been drawn from ASTM E 18 -97a ‘Standard test methods for Rockwell hardness and Rockwell4) For Rockwell hardness testing, no optical measurements are required; all readings are direct. There are two common methods applied to measure material hardness macroscopically: Rockwell and Brinell. Rockwell hardness differs from Brinell hardness testing in that the indentation size is measured in Brinell5.2.1 There are two general classifications of the Rockwell test: the Rockwell hardness test and the Rockwell superficial hardness test. 5.2.2 In the Rockwell hardness test the preliminary test force is 10 kgf (98 N). Total test forces are 60 kgf (589 N), 100 kgf (981 N) and 150 kgf (1471 N). In the Rockwell superficial

Best Practices for Rockwell Hardness Testing Hardness Testing Basics Hardness, as applied to most materials, and in particular metals, is a valuable, revealing, and commonly employed mechanical test that has been in use in various forms for more than 250 years. As a material property, its value and importance cannot be understated; the informationBefore a Rockwell hardness testing machine is verified, the machine shall be checked to ensure that it is properly set up in accordance with the manufacturer's instructions: Especially it should be checked that: a) the plunger holding the indenter is capable of sliding in its guide;EXAMPLE 70 HR30N = Rockwell superficial hardness of 70 measured on the 30 N scale with a total test force of 294,2 N. 4.4 The Rockwell superficial hardness for the T scale is denoted by the symbol HR preceded by the hardnessRockwell hardness testing machine series Versatile smart models 3 models to suit practically every application Features Specifications External dimensions (512) 434 65 218 352.4 162 150 13 780 (30) 113 214 180 502.5 235 235 502.5 180 214 113 (30) 780 13 150 162 352.4 218 434 65 (512) 212.8 (512) 434 65 218 352.4 162 150 13 780

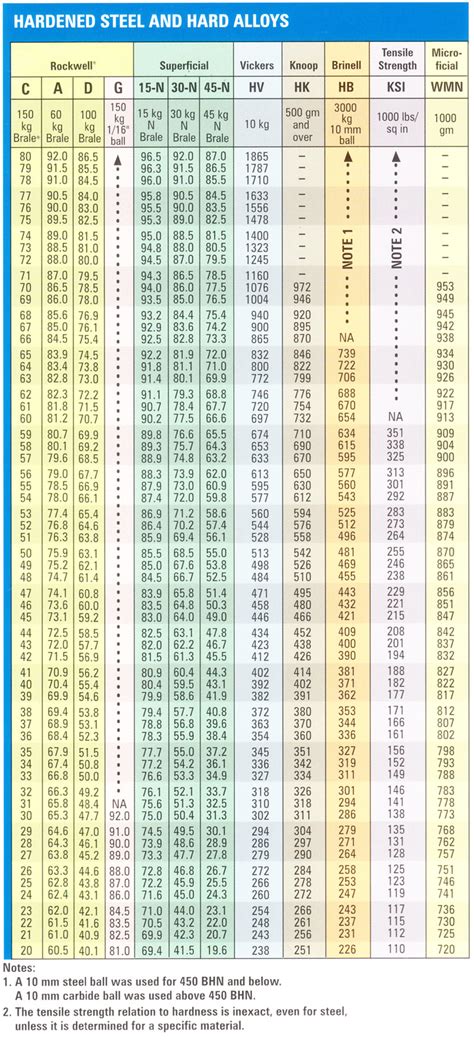

A standardized test procedure used to determine the hardenability of steel, the Jominy test (End Quench Test) can be performed using either the Vickers or Rockwell hardness test method. When selecting which to use, you should .These approximate relationships between hardness and tensile strength do not apply to nonferrous metals, with the possible exception of certain aluminum alloys. Related: Brinell Hardness Testing Equation. Table A Brinell Hardness to Rockwell Hardness Conversion Table

See also: Hardness. Rockwell Hardness Test. Rockwell hardness test is one of the most common indentation hardness tests, that has been developed for hardness testing. In contrast to Brinell test, the Rockwell tester measures the depth of penetration of an indenter under a large load (major load) compared to the penetration made by a preload . ASTM E10: This standard covers Brinell hardness testing in metallic samples. ASTM E18: This standard includes the various ways that Rockwell hardness can be measured by standard methods, specifically for metallic materials. ASTM E384: This standard is for hardness testing on a micro-scale, and therefore includes the Vickers and Knoop hardness .12 - newge testing Instruments, Inc. 2. TESTER OPERATION 2.1 General Procedure this tester uses the standard test method for rockwell and Superficial rockwell hardness testing per AStM e-18. 2.1.1 Basic Operation 1. turn power switch on .What is Rockwell hardness testing? The Rockwell Hardness Test is generally a non-destructive test performed on samples when it’s necessary to determine how hard a material is. It’s generally considered easier to perform compared to other methods, like Vickers or Brinell hardness testing. Another advantage is the small area of indentation needed to carry out the .

Download Free PDF. Designation: E18 − 16 Standard Test Methods for Rockwell Hardness of Metallic Materials 1,2. Diego Vera. This standard is issued under the fixed designation E18; the number immediately following the designation indicates the year of original adoption or, in the case of revision, the year of last revision. A number in .

rockwell hardness testing procedure pdf

Figure 8: Schematic description of Rockwell Hardness Testing. Rockwell Formula: Hardness Rockwell HR = E – e. “E” is a constant of 100 (diamond) or 130 (ball) units. “e” is the penetration depth in units of 0.002 mm Figure 9: Schematic description of Brinell Hardness Testing Rockwell Tester, Duramin-160 +Ans: a) in Vickers hardness test we apply loads vary between 5-120kgf. And in Brinell we apply between 500 – 3000 kgf. And in Rockwell hardness test we apply two loads, first is the initial load then the major load. b) in Vickers hardness test we use diamond pyramid with (136°) apex angle as an indenter. And in Brinell Hardness Test we use spherical 5 or 10 mm diameter .

The Starrett 3814 accurately measures hardness of materials in Rockwell hardness A, B, and C scales. Heat-treated steels are tested using a 120 diamond indenter in the C-scale (HRC 20-70). Soft materials are tested using a 1/16" . (Rockwell C) test blocks and place one on the anvil for testing. Diamond. ) A CWorldwide service network | 1-800-473-7838 service@buehle r.com Providing service and support that is dedicated to ensuring the highest quality

karl fischer titration coulometric volumetric distributor

The latest tweets from @any_cemar

hardness test rockwell pdf|hardness test lab report pdf